Rubber-Covered Roller Manufacturing

North America and Beyond

Quick Turnaround Times

Free Quotes

Request Quote

Hero Request Form

Thank you for contacting us.

We will get back to you as soon as possible.

Please try again later.

Precision-Engineered Rubber-Covered Rollers for Your Industry Needs

Contact Rubber Corporation specializes in manufacturing custom-built rubber-covered rollers designed for a wide range of industrial applications. Our expertly crafted rollers are ideal for crating, sealing, bag production, wrapping, adhesive application, and abrasive belt grinding and finishing processes. With our state-of-the-art equipment and extensive experience, we deliver high-quality rollers tailored to your specific requirements.

Whether you need small or large quantities, our team is ready to provide you with American-made products that meet the highest standards of quality and performance. Call us today to discuss your rubber-covered roller needs.

Tailored Solutions for Demanding Applications

When your operations demand precision and durability, CRC's rubber-covered rollers rise to the challenge. Our advanced manufacturing capabilities allow us to create rollers that excel in various industrial settings. We offer:

- Custom grooving in any angle, diamond, spiral, herringbone, or corrugation pattern

- Compounds formulated for ozone, heat, and extreme abrasion resistance

- Tailored materials to meet exact specifications

- Cutting-edge grinding, balancing, and serration equipment

- Customized molds for unique requirements

- QS-compliant manufacturing processes

Let CRC's expertise elevate your production capabilities. Reach out to our team to explore how our rubber-covered rollers can enhance your operations.

Unmatched Expertise and Service in Roller Manufacturing

Rubber Corporation brings decades of experience to every rubber-covered roller we produce. Our commitment to excellence is evident in every aspect of our service:

- Global services and shipping are available

- 40,000-square-foot manufacturing facility

- Rapid quoting process - free estimates within 2-3 business days

- Efficient production with a typical 3-week turnaround time

- Flexible shipping options to suit your schedule

- Serving Southeast Wisconsin and beyond since 1962

Experience the difference that comes with working with a trusted industry leader. Contact CRC to discuss your rubber-covered roller project and discover how we can support your business goals.

Partner With Rubber Corporation for Superior Results

Choosing CRC for your rubber-covered roller needs means partnering with a company dedicated to your success. Our team of experts is committed to delivering products that exceed your expectations and drive your business forward. With our extensive capabilities, attention to detail, and customer-focused approach, we ensure that every roller we produce is optimized for your specific application. Don't settle for less when it comes to critical components like rubber-covered rollers. Reach out today and let us show you why we've been a trusted name in the industry for over half a century.

Reviews

Quick Turnaround Times

We understand that time is money. Our efficient manufacturing process ensures you get your components fast, without sacrificing quality.

Contact Us Today for a Free Quote

Related Services

Roller-Covered Rollers

More details

Our custom state-of-the-art grinding, balancing, and serration equipment is the finest available in North America. We can groove any angle, diamond, spiral, herringbone, or corrugation pattern you might need. Our roll-covering materials are formulated to be resistant to ozone, heat, and extreme abrasion, and our compounds are tailored to meet exact specifications.

CRC is proud to furnish custom-built rollers for a variety of applications, including crating, sealing, bag making, wrapping, gluing, and abrasive belt grinding and finishing applications. Our cutting-edge roller coverings are available in a wide range of firmness levels, from 20 through 100-durometer hardness.

We also offer dependable delivery schedules!

Groove Patterns By Definition

More details

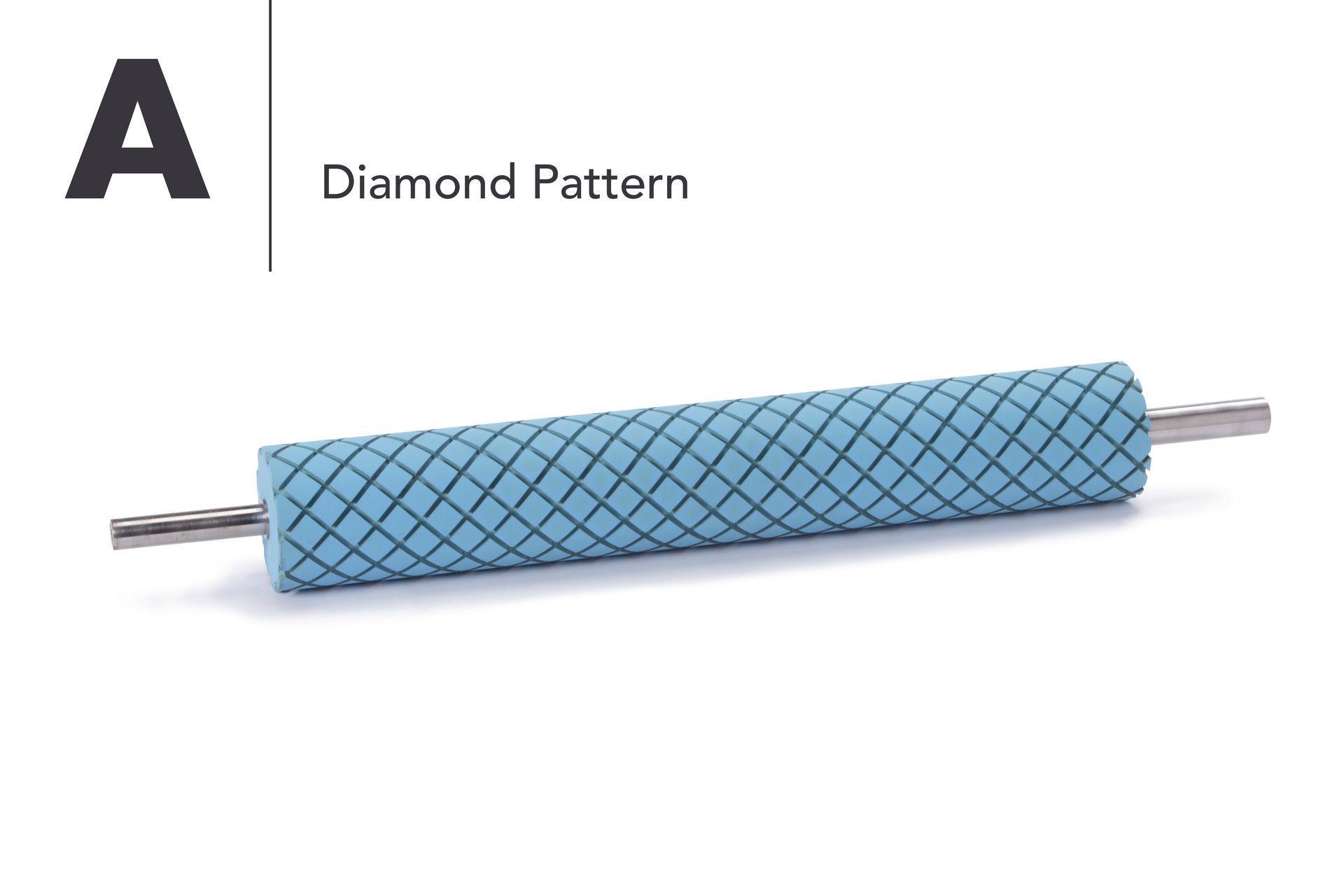

A – Diamond Pattern

Minimizes hydroplaning and provides better gripping for feed rolls.

B – Helical Pattern

Proper combinations of groove angles, along with land and groove widths, enhance the grinding or sanding ability of wide-coated abrasive belt machines.

C – Plain Face

Plain ground texture or satin-smooth finish is used for a multitude of purposes.

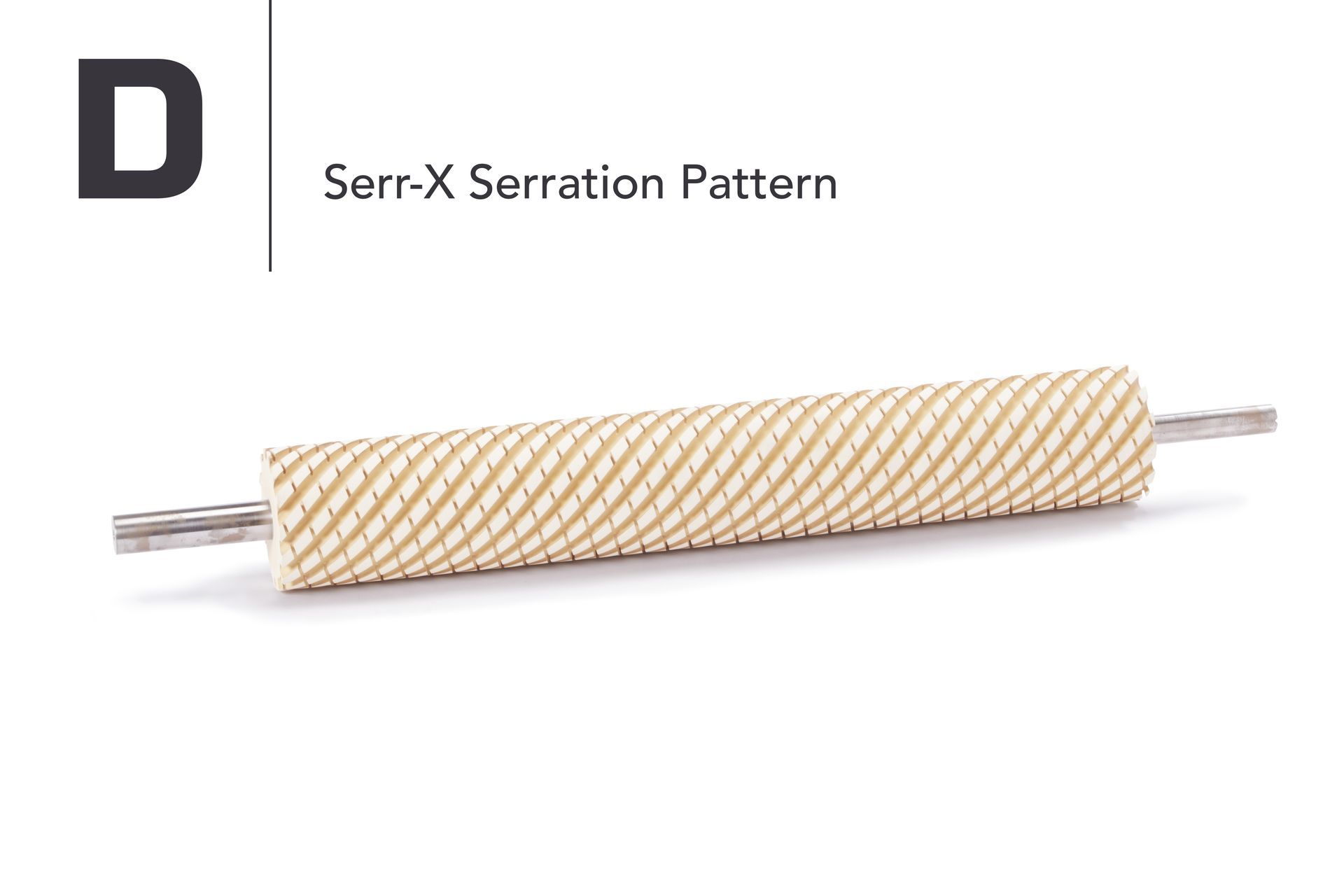

D – Serr-X Serration

Provides aggressive abrasive belt cutting action and conformability.

E – 90-Degree Fluted Grooves

Helps to keep the belt clean and is most often used for conveyor belt drive applications. It can also be used in scraping unwanted material from substrates.

F – Chevron Pattern

Offers great pulling action and helps keep conveyor belts tracking properly. It also smoothes out wrinkles in continuous webs.

Roller Recovery Services

More details

Roller recovery services include core inspection and repair, precision ground rubber diameter concentric with bearing journals, helical grooving, and dynamic balancing.

Available elastomers for roll coverings:

- Silicone

- Neoprene®

- Hypalon®

- Millable urethane

- SBR and EPDM

- Cast polyurethane

Natural Rubber

- Buna N/NBR

- Carboxylated nitrile (including HNBR and HXNBR)